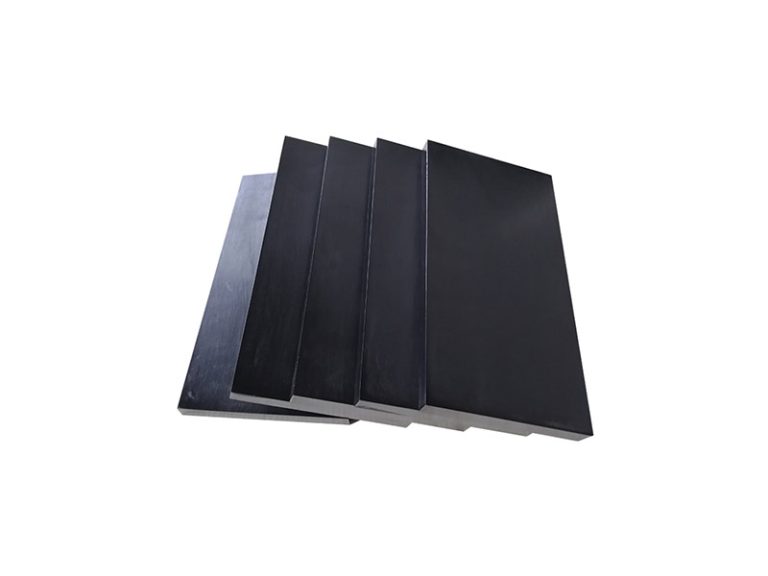

The role of graphite plate in vacuum furnace

Vacuum furnace is a kind of equipment for high temperature treatment under low pressure or oxygen-free environment. As an important part of the vacuum furnace, graphite plate plays the following main roles.

Heat conduction and uniform heating

Vacuum furnace snow to conduct heat evenly to the object to be treated, so that it reaches a predetermined temperature. Graphite plate has good thermal conductivity, can quickly conduct heat, and heat evenly distributed to the entire furnace chamber, so as to realize the uniform heating of the object to be treated.

High temperature stability guarantee

Vacuum furnace works under high temperature conditions, which requires the material to have good high-temperature stability, without expansion, deformation and other phenomena. Graphite plate has high thermal stability due to its special crystal structure and chemical properties, and can work stably in a high temperature environment to ensure the stability and long-term service life of the furnace chamber.

Anti-temperature oxidation protection

In the vacuum furnace, due to the oxygen-free and low-pressure environment, the graphite plate can form a layer of stable oxide protective film, reducing the reaction between graphite plate and oxygen, and slowing down the oxidation rate. This oxide protective film has good stability, can effectively prevent the graphite plate oxidation damage, improve the service life of graphite plate.

Corrosion resistance

Vacuum furnace in some special processes need to use strong corrosive media, such as acid, alkali and so on. Graphite plate has good corrosion resistance due to its chemical inertia, can maintain the integrity and performance of the material under the action of corrosive media, to ensure the normal operation of the vacuum furnace.

Graphite insulation plates and bases for vacuum smelting, graphite parts for high-temperature-resistant furnace tubes, rods, plates, brackets and fixtures, graphite shields, heating elements, induction heaters, and so on.

Large size materials for pressure sintering process and graphite molds for sandwich pressure sintering.

Graphite molds and graphite rods for the production of diamond pillars, alloy diamond heating elements and support elements.

Graphite ships and graphite molds for sintering electronic components.