Description

The high-purity graphite crucible is a kind of crucible made from high-purity graphite as the main raw material. It has a series of significant advantages, such as good thermal stability brought by high-purity graphite, specially designed for the use conditions of rapid heating and rapid cooling, ensuring the reliability of product quality; the uniform and fine matrix design delays the degree of erosion, giving it excellent corrosion resistance; it can withstand extremely high thermal shock strength, and various process treatments can be carried out with confidence, showing excellent impact resistance; the addition of special materials improves the quality of the crucible, and it performs extremely well in acid resistance indicators, greatly extending the service life; a high content of fixed carbon ensures good thermal conductivity, shortens the melting time of metals, and significantly reduces energy consumption; strict control of material composition ensures that no pollution will be generated when dissolving metals; the use of advanced high-pressure forming method manufacturing technology and quality assurance system fully guarantees the stability of quality.

Features

Applications

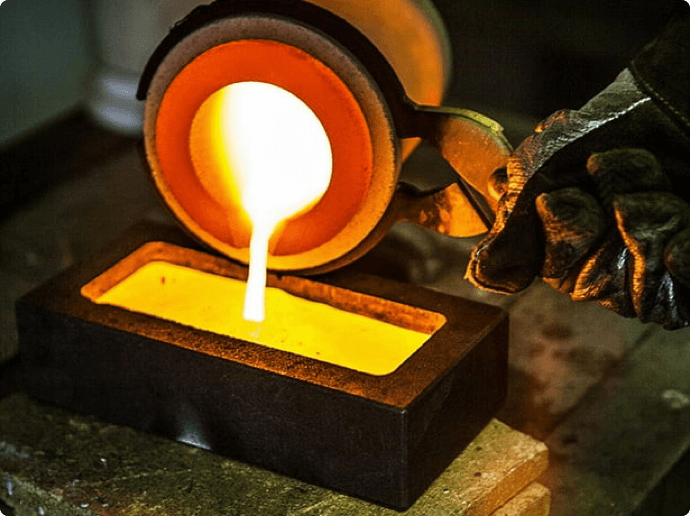

High-purity graphite crucibles are widely used in various fields. In the metallurgical industry, it is used for the smelting of alloy tool steels and the smelting of non-ferrous metals and their alloys; in the casting field, it can be used for the preparation of high-precision and high-quality castings; in the laboratory, it is often used in high-temperature reactions, melting experiments, and material synthesis and other research.

With its high purity, excellent performance and stable quality, the high-purity graphite crucible plays an important role in industrial production and scientific research experiments such as high-temperature melting and metal smelting. It can not only improve production efficiency and product quality, but also effectively control metal pollution, and is an ideal melting and experimental tool.

Specifications

Parameter

| Type | Bulk Density | Specific Resistivity | Heat Conductivity(100℃) | Coefficient of Thermal Expansion | Shore Hardness | Flexural Strength | Compressive Strength | Modulus of Elasticity | Porosity | Ash | Granularity | Recommended |

| g/cm³ | μQ·m | W/m.k | HSD | HSD | Mpa | Mpa | Gpa | % | PPM | μm | Applications | |

| YT-WX-4 | 1.75 | 8-11 | 110-120 | 5.46 | 42 | 65 | 38 | 9 | 17 | 50 | 13-15 | Common (use) |

| YT-WX-5 | 1.85 | 8-10 | 130-140 | 4.75 | 48 | 85 | 46 | 11.8 | 13 | 50 | 13-15 | Common (use) |

| YT-WX-6 | 1.90 | 8-9 | 130-140 | 4.80 | 53 | 95 | 55 | 12 | 11 | 50 | 8-10 | Metallurgy |

| YT-WX-7 | 1.82 | 11-13 | 110-120 | 5.80 | 65 | 51 | 115 | 12 | 12 | 50 | / | Common (use) |

| YT-H-5 | 1.68 | 13-15 | 80-100 | 5.80 | 60 | 80 | 38 | 8.8 | 18 | 50 | 8-10 | EDM |

| YT-H-7 | 1.85 | 11-13 | 100-120 | 5.90 | 68 | 135 | 62 | 12 | 12 | 50 | 7 | EDM & Photovoltaic |

| YT-H-8 | 1.90 | 11-13 | 110-120 | 5.85 | 72 | 160 | 70 | 13 | 11 | 50 | 5 | EDM & Hot Press |

| YT-BD900 | 1.83 | 8-11 | 120 | 4.90 | 50 | 87 | 45 | 11 | 13 | 50 | / | Hot Bending Glass: Automotive |

| YT-BD950 | 1.85 | 8-11 | 130 | 5.00 | 51 | 100 | 55 | 13 | 13 | 50 | / | Hot Bent Glass: Rear Covers |

| YT-BD960 | 1.79 | 8-11 | 100 | 5.30 | 55 | 101 | 60 | 12 | 14 | 50 | / | Hot Bent Glass: Front Cover |

| RW800 | 1.85 | 11-13 | 95 | 6.00 | 70 | 140 | 70 | 12 | 15 | 50 | / | Semiconductor |

| RW810 | 1.82 | 11-13 | 95 | 6.10 | 70 | 145 | 68 | 11 | 15 | 50 | / | Semiconductor |

| RW860 | 1.82 | 12-15 | 90 | 6.20 | 70 | 150 | 65 | 13 | 15 | 50 | / | Semiconductor |