Description

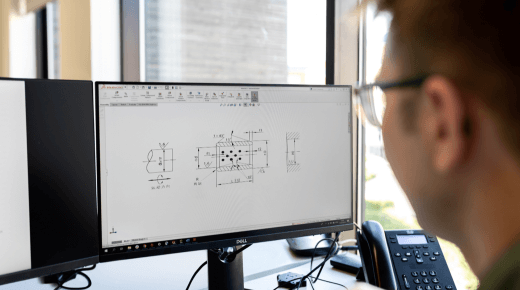

The graphite vacuum pump core - graphite rotor produced by Baofeng Yuantai Graphite has outstanding specialties and significant advantages. It is made of high-quality graphite materials through elaborate design and precise manufacturing. This graphite rotor operates smoothly in the vacuum pump and can provide efficient vacuum extraction capacity. It has excellent wear resistance and corrosion resistance and can operate stably for a long time in harsh working environments. Baofeng Yuantai Graphite ensures the excellent quality and reliability of the product with advanced production technology and strict quality control.

Features

Applications

The graphite vacuum pump core - graphite rotor of Baofeng Yuantai Graphite has the characteristics of efficient vacuum pumping, wear and corrosion resistance, and smooth operation, and is widely used in fields such as vacuum coating, semiconductor manufacturing, chemical industry and scientific research experiments. Its high-quality performance and reliable quality provide a strong guarantee for the vacuum process in various industries.

Specifications

Parameter

| Type | Bulk Density | Specific Resistivity | Heat Conductivity(100℃) | Coefficient of Thermal Expansion | Shore Hardness | Flexural Strength | Compressive Strength | Modulus of Elasticity | Porosity | Ash | Granularity | Recommended |

| g/cm³ | μQ·m | W/m.k | HSD | HSD | Mpa | Mpa | Gpa | % | PPM | μm | Applications | |

| YT-WX-4 | 1.75 | 8-11 | 110-120 | 5.46 | 42 | 65 | 38 | 9 | 17 | 50 | 13-15 | Common (use) |

| YT-WX-5 | 1.85 | 8-10 | 130-140 | 4.75 | 48 | 85 | 46 | 11.8 | 13 | 50 | 13-15 | Common (use) |

| YT-WX-6 | 1.90 | 8-9 | 130-140 | 4.80 | 53 | 95 | 55 | 12 | 11 | 50 | 8-10 | Metallurgy |

| YT-WX-7 | 1.82 | 11-13 | 110-120 | 5.80 | 65 | 51 | 115 | 12 | 12 | 50 | / | Common (use) |

| YT-H-5 | 1.68 | 13-15 | 80-100 | 5.80 | 60 | 80 | 38 | 8.8 | 18 | 50 | 8-10 | EDM |

| YT-H-7 | 1.85 | 11-13 | 100-120 | 5.90 | 68 | 135 | 62 | 12 | 12 | 50 | 7 | EDM & Photovoltaic |

| YT-H-8 | 1.90 | 11-13 | 110-120 | 5.85 | 72 | 160 | 70 | 13 | 11 | 50 | 5 | EDM & Hot Press |

| YT-BD900 | 1.83 | 8-11 | 120 | 4.90 | 50 | 87 | 45 | 11 | 13 | 50 | / | Hot Bending Glass: Automotive |

| YT-BD950 | 1.85 | 8-11 | 130 | 5.00 | 51 | 100 | 55 | 13 | 13 | 50 | / | Hot Bent Glass: Rear Covers |

| YT-BD960 | 1.79 | 8-11 | 100 | 5.30 | 55 | 101 | 60 | 12 | 14 | 50 | / | Hot Bent Glass: Front Cover |

| RW800 | 1.85 | 11-13 | 95 | 6.00 | 70 | 140 | 70 | 12 | 15 | 50 | / | Semiconductor |

| RW810 | 1.82 | 11-13 | 95 | 6.10 | 70 | 145 | 68 | 11 | 15 | 50 | / | Semiconductor |

| RW860 | 1.82 | 12-15 | 90 | 6.20 | 70 | 150 | 65 | 13 | 15 | 50 | / | Semiconductor |