Description

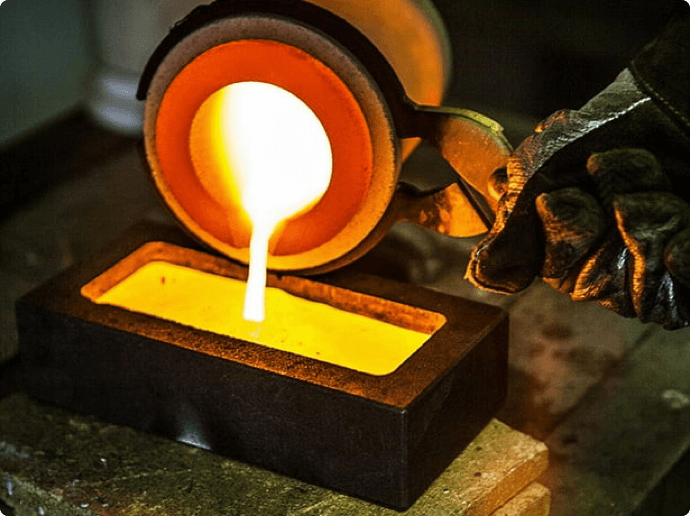

A graphite crucible is a container made of graphite material, usually with a regular shape and a certain depth. It is elaborately processed using advanced manufacturing techniques, with a relatively smooth surface and uniform texture. Graphite crucibles are widely used in industrial production and can withstand various complex and harsh conditions.

Features

Applications

Graphite crucibles play an indispensable role in multiple industrial fields due to their outstanding performance. They effectively improve production efficiency and guarantee product quality, providing strong support for the development of related industries. With the continuous advancement of technology, the performance of graphite crucibles will further improve, and the application scope is also expected to continue to expand.

Specifications

Parameter

| Type | Bulk Density | Specific Resistivity | Heat Conductivity(100℃) | Coefficient of Thermal Expansion | Shore Hardness | Flexural Strength | Compressive Strength | Modulus of Elasticity | Porosity | Ash | Granularity | Recommended |

| g/cm³ | μQ·m | W/m.k | HSD | HSD | Mpa | Mpa | Gpa | % | PPM | μm | Applications | |

| WX-4 | 1.75 | 8-11 | 110-120 | 5.46 | 42 | 65 | 38 | 9 | 17 | 50 | 13-15 | Common (use) |

| WX-5 | 1.85 | 8-10 | 130-140 | 4.75 | 48 | 85 | 46 | 11.8 | 13 | 50 | 13-15 | Common (use) |

| WX-6 | 1.90 | 8-9 | 130-140 | 4.80 | 53 | 95 | 55 | 12 | 11 | 50 | 8-10 | Metallurgy |

| WX-7 | 1.82 | 11-13 | 110-120 | 5.80 | 65 | 51 | 115 | 12 | 12 | 50 | / | Common (use) |

| Hong-5 | 1.68 | 13-15 | 80-100 | 5.80 | 60 | 80 | 38 | 8.8 | 18 | 50 | 8-10 | EDM |

| Hong-7 | 1.85 | 11-13 | 100-120 | 5.90 | 68 | 135 | 62 | 12 | 12 | 50 | 7 | EDM & Photovoltaic |

| Hong-8 | 1.90 | 11-13 | 110-120 | 5.85 | 72 | 160 | 70 | 13 | 11 | 50 | 5 | EDM & Hot Press |

| BD900 | 1.83 | 8-11 | 120 | 4.90 | 50 | 87 | 45 | 11 | 13 | 50 | / | Hot Bending Glass: Automotive |

| BD950 | 1.85 | 8-11 | 130 | 5.00 | 51 | 100 | 55 | 13 | 13 | 50 | / | Hot Bent Glass: Rear Covers |

| BD960 | 1.79 | 8-11 | 100 | 5.30 | 55 | 101 | 60 | 12 | 14 | 50 | / | Hot Bent Glass: Front Cover |

| RW800 | 1.85 | 11-13 | 95 | 6.00 | 70 | 140 | 70 | 12 | 15 | 50 | / | Semiconductor |

| RW810 | 1.82 | 11-13 | 95 | 6.10 | 70 | 145 | 68 | 11 | 15 | 50 | / | Semiconductor |

| RW860 | 1.82 | 12-15 | 90 | 6.20 | 70 | 150 | 65 | 13 | 15 | 50 | / | Semiconductor |