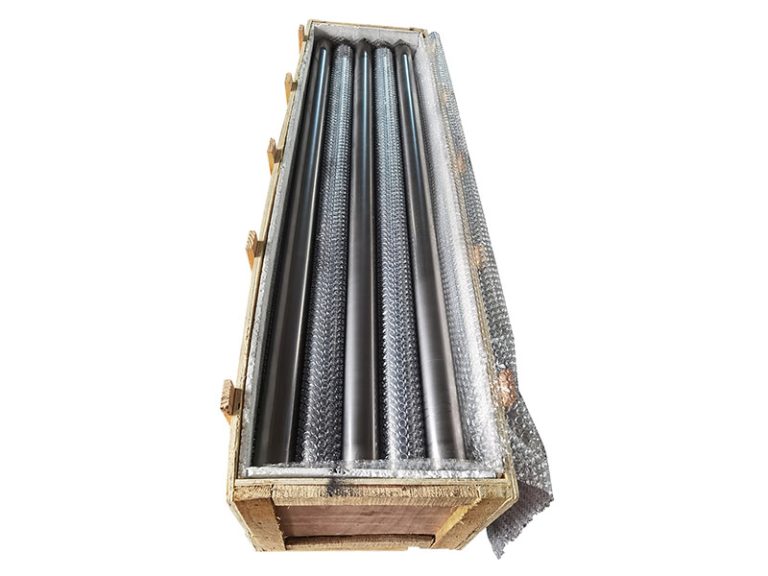

Description

Graphite stopper rods are components meticulously crafted from graphite materials. They usually present a slender rod-like structure, with the surface finely treated, smooth and uniform. Graphite stopper rods have good high-temperature resistance, thermal shock resistance, and certain mechanical strength, and can work stably in high-temperature and complex working conditions.

Features

01

High-temperature resistance: Can withstand high-temperature environments without deformation.

02

Good thermal shock resistance: Can adapt to sudden changes in temperature.

03

Low friction coefficient: Reduces wear with other components.

04

High chemical stability: Not easy to react with other substances.

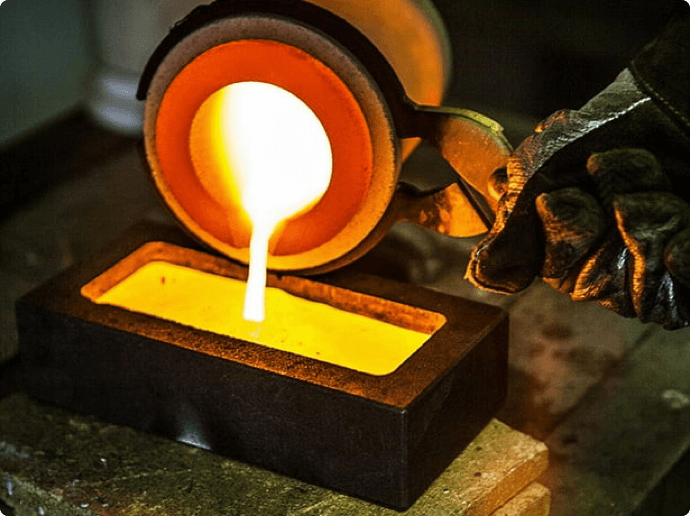

Applications

01

Metallurgical industry: Used to control the flow of molten steel.

02

Casting industry: Plays a regulating role in the casting process.

03

Glass manufacturing: Assists in controlling the outflow of glass melt.

Graphite stopper rods, with their unique performance characteristics, play an important role in multiple industrial fields and provide a strong guarantee for the precise control and efficient operation of the production process.

Specifications

Material

High quality graphite

Capacity

Accept customization

Size

Accept customization

Compatibility

Suitable for all kinds of furnaces and melting devices

Parameter

| Type | Bulk Density | Specific Resistivity | Heat Conductivity(100℃) | Coefficient of Thermal Expansion | Shore Hardness | Flexural Strength | Compressive Strength | Modulus of Elasticity | Porosity | Ash | Granularity | Recommended |

| g/cm³ | μQ·m | W/m.k | HSD | HSD | Mpa | Mpa | Gpa | % | PPM | μm | Applications | |

| YT-WX-4 | 1.75 | 8-11 | 110-120 | 5.46 | 42 | 65 | 38 | 9 | 17 | 50 | 13-15 | Common (use) |

| YT-WX-5 | 1.85 | 8-10 | 130-140 | 4.75 | 48 | 85 | 46 | 11.8 | 13 | 50 | 13-15 | Common (use) |

| YT-WX-6 | 1.90 | 8-9 | 130-140 | 4.80 | 53 | 95 | 55 | 12 | 11 | 50 | 8-10 | Metallurgy |

| YT-WX-7 | 1.82 | 11-13 | 110-120 | 5.80 | 65 | 51 | 115 | 12 | 12 | 50 | / | Common (use) |

| YT-H-5 | 1.68 | 13-15 | 80-100 | 5.80 | 60 | 80 | 38 | 8.8 | 18 | 50 | 8-10 | EDM |

| YT-H-7 | 1.85 | 11-13 | 100-120 | 5.90 | 68 | 135 | 62 | 12 | 12 | 50 | 7 | EDM & Photovoltaic |

| YT-H-8 | 1.90 | 11-13 | 110-120 | 5.85 | 72 | 160 | 70 | 13 | 11 | 50 | 5 | EDM & Hot Press |

| YT-BD900 | 1.83 | 8-11 | 120 | 4.90 | 50 | 87 | 45 | 11 | 13 | 50 | / | Hot Bending Glass: Automotive |

| YT-BD950 | 1.85 | 8-11 | 130 | 5.00 | 51 | 100 | 55 | 13 | 13 | 50 | / | Hot Bent Glass: Rear Covers |

| YT-BD960 | 1.79 | 8-11 | 100 | 5.30 | 55 | 101 | 60 | 12 | 14 | 50 | / | Hot Bent Glass: Front Cover |

| RW800 | 1.85 | 11-13 | 95 | 6.00 | 70 | 140 | 70 | 12 | 15 | 50 | / | Semiconductor |

| RW810 | 1.82 | 11-13 | 95 | 6.10 | 70 | 145 | 68 | 11 | 15 | 50 | / | Semiconductor |

| RW860 | 1.82 | 12-15 | 90 | 6.20 | 70 | 150 | 65 | 13 | 15 | 50 | / | Semiconductor |