Description

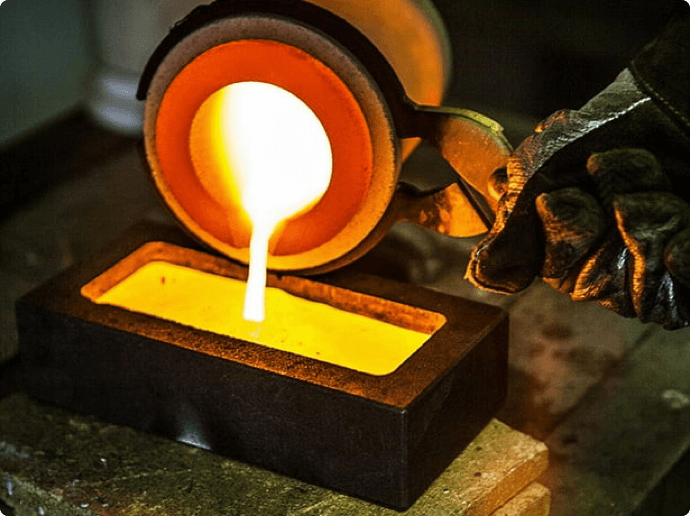

Graphite crucible, also known as molten copper ladle, molten copper, etc., refers to a class of crucibles fired with graphite, clay, silica and waxy stone as raw materials. Graphite crucibles are mainly used to melt non-ferrous metals and their alloys such as copper, brass, gold, silver, zinc and lead. Graphite crucible is characterized by high temperature resistance, strong thermal conductivity, good corrosion resistance and long service life.

Graphite crucible is characterized by high temperature resistance, strong thermal conductivity, good corrosion resistance and long service life. In the process of high-temperature use, the coefficient of thermal expansion is small, and it has certain strain-resistant performance to rapid cold and heat. It has strong corrosion resistance to acidic and alkaline solution, excellent chemical stability, and does not participate in any chemical reaction in the melting process.

The inner wall of graphite crucible is smooth, the melted metal liquid is not easy to leak and adhere to the inner wall of the crucible, so that the metal liquid has good mobility and casting, and it is suitable for casting and molding in different kinds of molds.

Features

Care and Preservation

Graphite crucible should pay attention to moisture proof.Graphite crucible is most afraid of moisture, and the quality is greatly affected by moisture. If using the crucible with moisture, there will be phenomena such as rupture, bursting piece, dropping gang and dropping bottom etc., which will cause the loss of melted metal, and even industrial accidents. So the graphite crucible must pay attention to the moisture proof in the process of storage and use.

Specifications

Parameter

| Type | Bulk Density | Specific Resistivity | Heat Conductivity(100℃) | Coefficient of Thermal Expansion | Shore Hardness | Flexural Strength | Compressive Strength | Modulus of Elasticity | Porosity | Ash | Granularity | Recommended |

| g/cm³ | μQ·m | W/m.k | HSD | HSD | Mpa | Mpa | Gpa | % | PPM | μm | Applications | |

| YT-WX-4 | 1.75 | 8-11 | 110-120 | 5.46 | 42 | 65 | 38 | 9 | 17 | 50 | 13-15 | Common (use) |

| YT-WX-5 | 1.85 | 8-10 | 130-140 | 4.75 | 48 | 85 | 46 | 11.8 | 13 | 50 | 13-15 | Common (use) |

| YT-WX-6 | 1.90 | 8-9 | 130-140 | 4.80 | 53 | 95 | 55 | 12 | 11 | 50 | 8-10 | Metallurgy |

| YT-WX-7 | 1.82 | 11-13 | 110-120 | 5.80 | 65 | 51 | 115 | 12 | 12 | 50 | / | Common (use) |

| YT-H-5 | 1.68 | 13-15 | 80-100 | 5.80 | 60 | 80 | 38 | 8.8 | 18 | 50 | 8-10 | EDM |

| YT-H-7 | 1.85 | 11-13 | 100-120 | 5.90 | 68 | 135 | 62 | 12 | 12 | 50 | 7 | EDM & Photovoltaic |

| YT-H-8 | 1.90 | 11-13 | 110-120 | 5.85 | 72 | 160 | 70 | 13 | 11 | 50 | 5 | EDM & Hot Press |

| YT-BD900 | 1.83 | 8-11 | 120 | 4.90 | 50 | 87 | 45 | 11 | 13 | 50 | / | Hot Bending Glass: Automotive |

| YT-BD950 | 1.85 | 8-11 | 130 | 5.00 | 51 | 100 | 55 | 13 | 13 | 50 | / | Hot Bent Glass: Rear Covers |

| YT-BD960 | 1.79 | 8-11 | 100 | 5.30 | 55 | 101 | 60 | 12 | 14 | 50 | / | Hot Bent Glass: Front Cover |

| RW800 | 1.85 | 11-13 | 95 | 6.00 | 70 | 140 | 70 | 12 | 15 | 50 | / | Semiconductor |

| RW810 | 1.82 | 11-13 | 95 | 6.10 | 70 | 145 | 68 | 11 | 15 | 50 | / | Semiconductor |

| RW860 | 1.82 | 12-15 | 90 | 6.20 | 70 | 150 | 65 | 13 | 15 | 50 | / | Semiconductor |