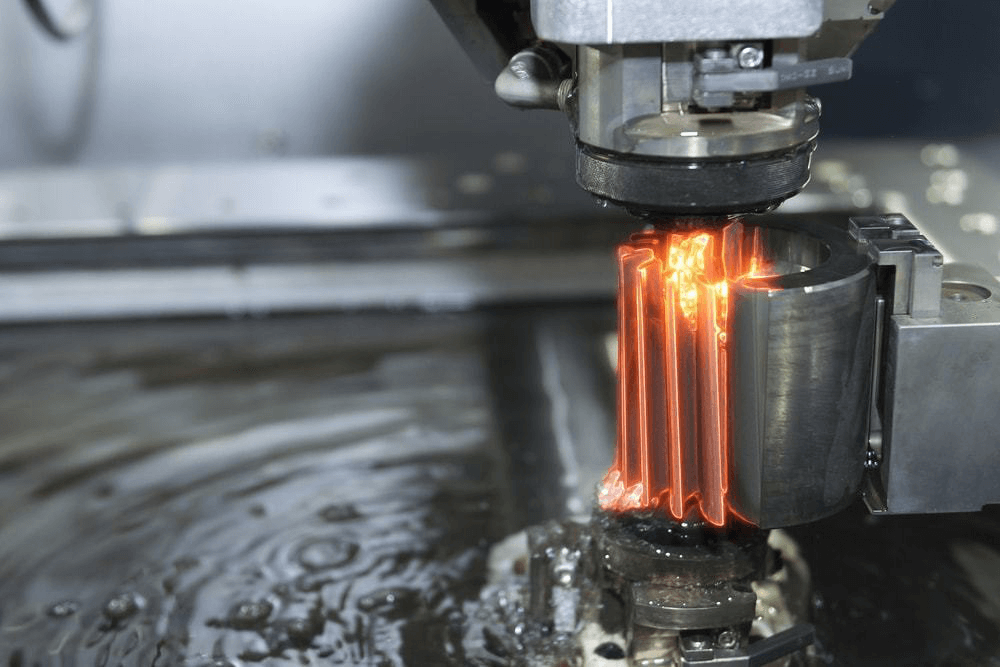

As an important part of the manufacturing industry, the EDM graphite industry has become an indispensable part of the modern industrial system after a century of development. Since the beginning of the 20th century, the gradual maturation of EDM technology has promoted the wide application of graphite materials in the field of EDM. With the progress of science and technology and the continuous development of the manufacturing industry, the EDM graphite industry has realized significant growth, the industrial scale continues to expand, and the technical level continues to improve.

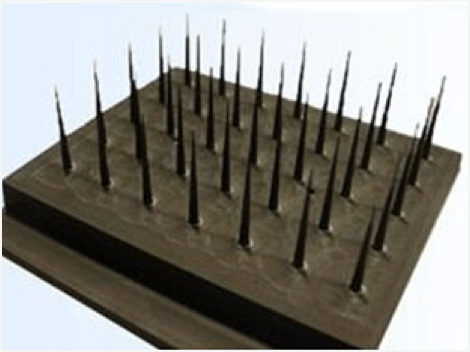

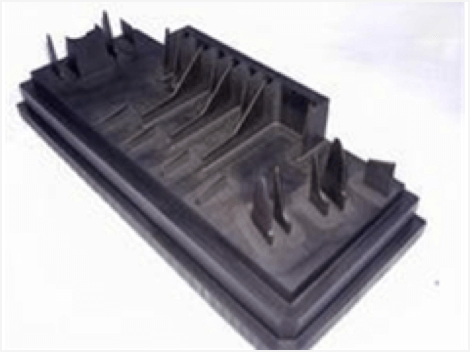

In the course of development of the industry, the EDM graphite industry has gradually formed a perfect industrial chain structure, covering various links from raw material supply to graphite material production, processing equipment manufacturing and processing services. The supply of raw materials to ensure the stable development of the industry, graphite materials production process continues to improve, processing equipment manufacturing technology innovation also provides strong support for the industry. The continuous expansion of processing services to meet the growing market demand for high-quality, high-precision graphite products.

- Fast production speed and high efficiency.

- Strict packaging to ensure that the products are not damaged.

- Convenient address location, can be shipped as soon as possible.

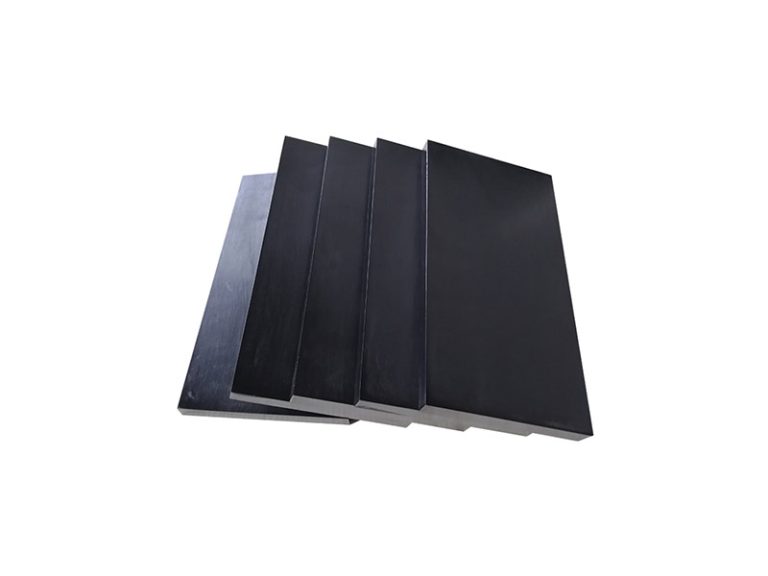

Yuantai graphite has the following advantages in the material application of EDM:

Better machining performance:it shows that the roughing speed is 2-3 times that of copper electrode; the finishing speed of high-speed milling is 5 times that of copper electrode, burr-free and easy to polish after machining.

Lower loss:in EDM, basically unrealizable loss.

Lower coefficient of thermal expansion:A lower coefficient of thermal expansion ensures the stability of the electrode during machining.

Higher temperature resistance:graphite has a melting point of up to 3850°C and can withstand higher currents.

Fewer electrodes:Fewer electrodes are needed during machining and less measuring work is required.