The continuous casting industry has in recent years been promoting advanced production methods such as the direct continuous (or semi-continuous) manufacture of rods or tubes from the molten metal state. Artificial graphite as a non-ferrous metal continuous casting or semi-continuous casting with molds is considered a suitable material. Production practice has proved that the continuous casting industry using graphite molds, because of its good thermal conductivity (thermal conductivity determines the solidification rate of the metal or alloy), the mold's self-lubricating properties and other factors, not only to make the casting speed, and due to the ingot of high dimensional accuracy, smooth surface, and uniform crystalline organization, can be directly carried out in the next step of the process. This not only greatly improves the rate of finished products, reducing the loss of scrap, and product quality has also improved substantially. Continuous casting method has vertical continuous casting method and horizontal continuous casting method two kinds.

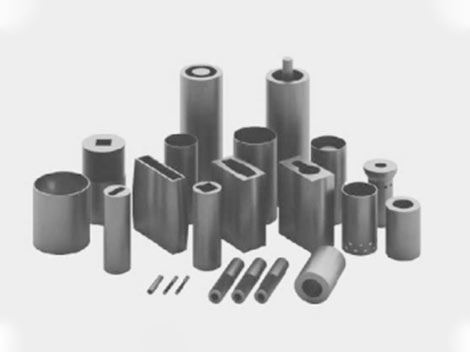

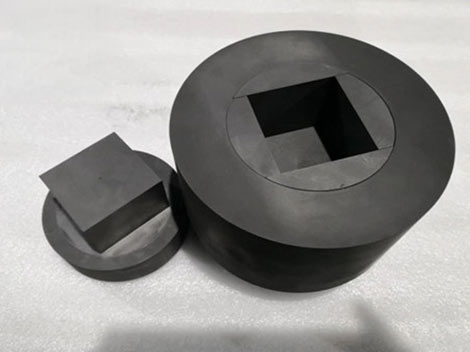

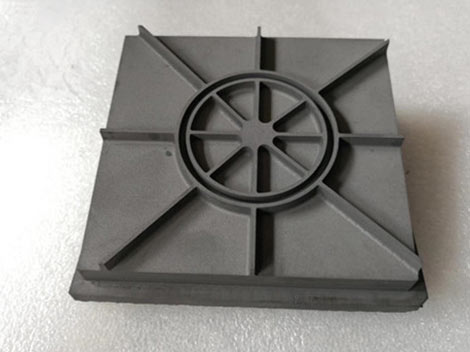

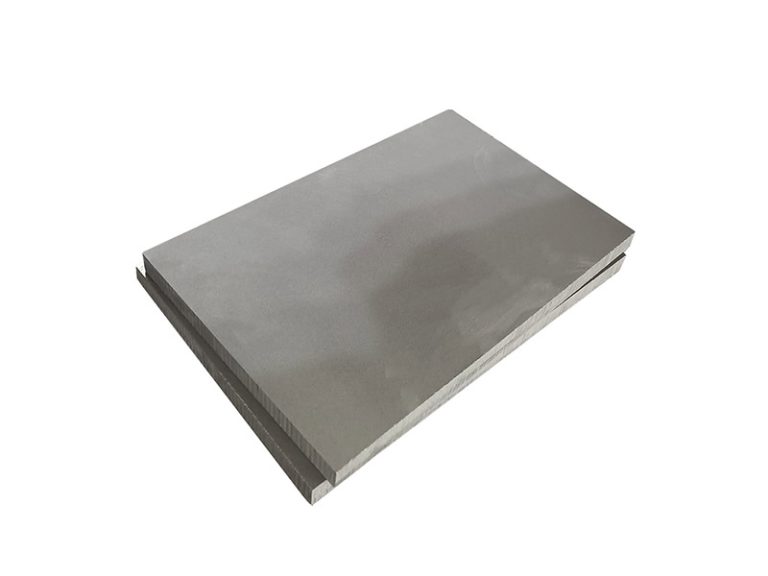

Continuous casting graphite molds are also used with the metal smelting industry, where molten metal can be cast in graphite molds. Graphite molds are reusable, but there are some designs that are only disposable. Creative small grain castings can be cast directly using graphite molds.

The coefficient of thermal expansion is an important factor in determining the use of graphite as a mold material. A casting mold is a medium with a very heterogeneous temperature, hot from the inside due to the molten material and cold from the outside due to the cooling process applied to it. Graphite exhibits a low coefficient of thermal expansion that allows the mold to function without distortion or cracking. Another very important factor is self-lubrication. Graphite is a solid lubricant that creates low friction between the mold and the casting material. Subsequently, graphite allows for smooth extraction of the casting.

There are a variety of factors that determine the life of a continuous casting graphite mold. From the composition of the casting material, to the casting temperature, to the cooling rate, all affect the life of the graphite mold. The particular grade of graphite used is also determined by a variety of factors. The main factor is the material process area in which the mold is to be cast. For example, for gray cast iron or high nickel alloys, a graphite that is resistant to high temperatures is required, while for brass, a relatively dense graphite with enough open porosity to allow zinc to evaporate would be a good choice.

Our technicians have developed special materials for copper continuous casting through in-depth research on materials. The metal molds manufactured by our customers have high hardness, wear and oxidation resistance, increased service life and a quantum leap in product quality.