Graphite electrode is an important carbon material that is widely used in industrial production and scientific research due to its unique physical and chemical properties. In this article, we will discuss the technical advantages and application prospects of graphite electrodes together.

Advantages of graphite electrode in power industry:

1. High conductivity: graphite electrodes have excellent electrical conductivity and can supply stable current conduction under high temperature and high pressure environment. This makes graphite electrode become an important material in electrochemical industry, metallurgical industry and other fields.

2. High temperature resistance: graphite electrodes have excellent high temperature resistance and can withstand harsh working conditions at high temperatures. Therefore, graphite electrodes are widely used in metallurgical furnaces, ore smelting, electrolytic cells and other high temperature processes.

3. Corrosion resistance: graphite electrode has good corrosion resistance, can withstand a variety of acids, alkalis and other corrosive media, suitable for chemical industry, electroplating and other categories of corrosive processes.

4. Long life: Because graphite electrodes have better wear resistance and oxidation resistance, their life span is usually longer than other electrode materials. This reduces maintenance costs and extends the life of the equipment.

5. Renewability: graphite electrodes can be recycled through the recovery and reuse of resources, reducing the need for graphite and other raw materials, in line with the requirements of sustainable development.

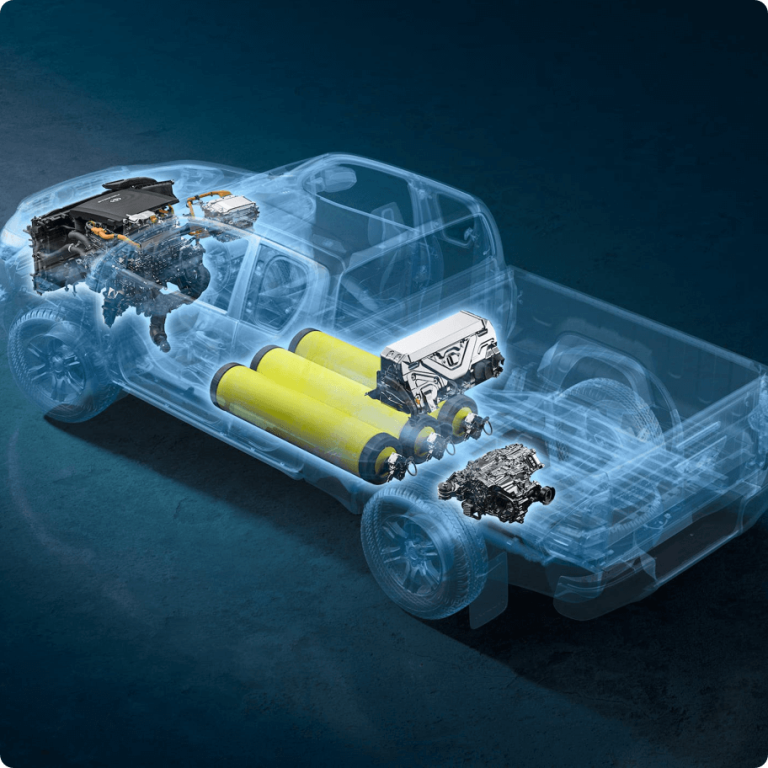

In terms of usage prospect, graphite electrode is widely used in metallurgy, chemical industry, electric power, electrolysis and other professions. With the development of the global economy and the promotion of industrialization, the demand for graphite electrodes will continue to increase. Especially in the new power category, graphite electrodes are used in the production of high-performance batteries such as lithium-ion batteries and fuel cells, which have an important role. In addition, graphite electrodes are also widely used in the production process of steel exercise, aluminum electrolysis, silicon and other important materials. It is expected that in the next few years, graphite electrode skills will continue to be promoted and used, and play a greater role in emerging areas such as power storage and electric vehicles.

Our services include:

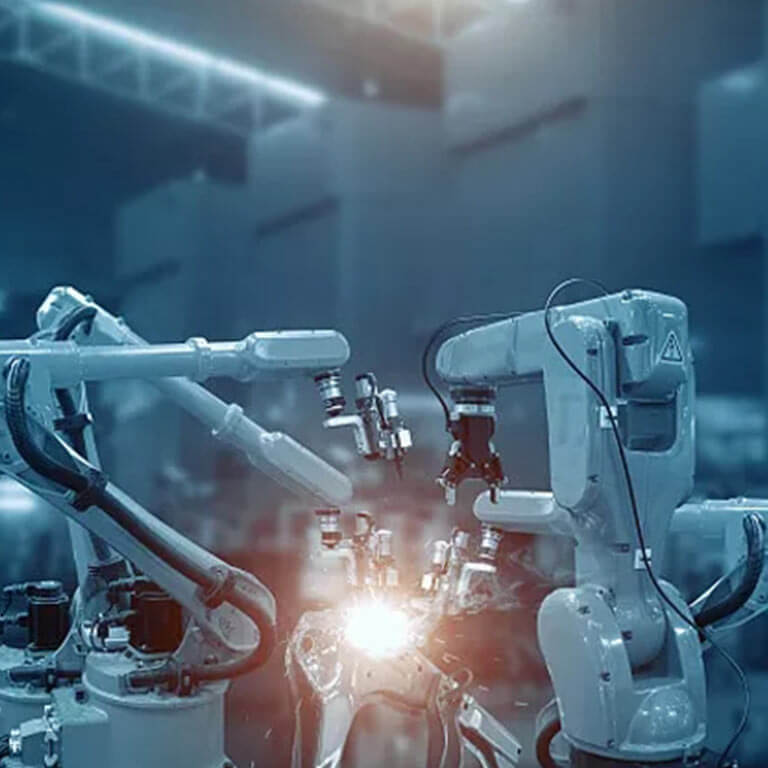

- Fast production speed and high efficiency.

- Strict packaging to ensure that the products are not damaged.

- Convenient address location, can be shipped as soon as possible.