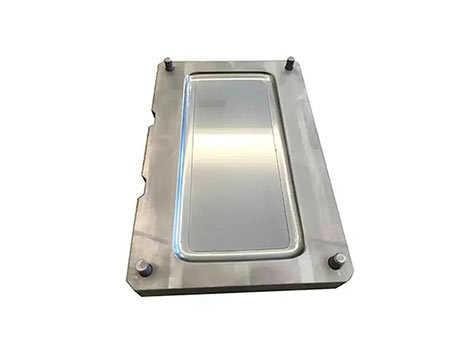

The graphite mold for hot-bent glass is a new type of mold that has emerged in the glass manufacturing industry in recent years. This mold is made from high-purity graphite and undergoes precise processing and heat treatment processes. It has excellent high-temperature performance and geometric accuracy, bringing revolutionary changes to the hot-bending forming of glass.

Why use graphite materials for glass molds

- Excellent thermal and electrical conductivity

- Good thermal stability and resistance to heating shock with a low coefficient of linear expansion

- Chemical resistance and less reactivity with most metals

- The strength increases with the increase in temperature at high temperatures (above 800°C for the sintering temperature of most copper-based matrices)

- Good lubrication and abrasion resistance

- Easy to process, with good mechanical processing performance, and can be made into molds with complex shapes and high precision Summary: Graphite materials have chemical stability, are not easily infiltrated by molten glass, do not change the composition of the glass, have good heat shock resistance, and have small dimensional changes with temperature. They are a good choice for hot-bent glass.

Industry status

With the continuous upgrading of the consumer market, the demand for glass covers in electronic products such as smart phones and tablet computers is increasing day by day. In these fields, hot-bent glass, as a material with a unique appearance and excellent performance, is favored by both producers and consumers. Correspondingly, the market demand for graphite molds for hot-bent glass also shows a rapid growth trend.

Technological process

The manufacturing process of the graphite mold for hot-bent glass mainly includes the following steps:

Select high-purity graphite as the raw material and conduct pretreatment to improve the density and stability of the material.

Use the Swiss Mikron high-speed machine tool for precise processing to ensure the geometric accuracy and surface roughness of the mold.

Conduct heat treatment on the processed mold to improve its high-temperature performance and service life.

Conduct quality inspection on the finished mold to ensure it meets the usage requirements of customers.

Product application

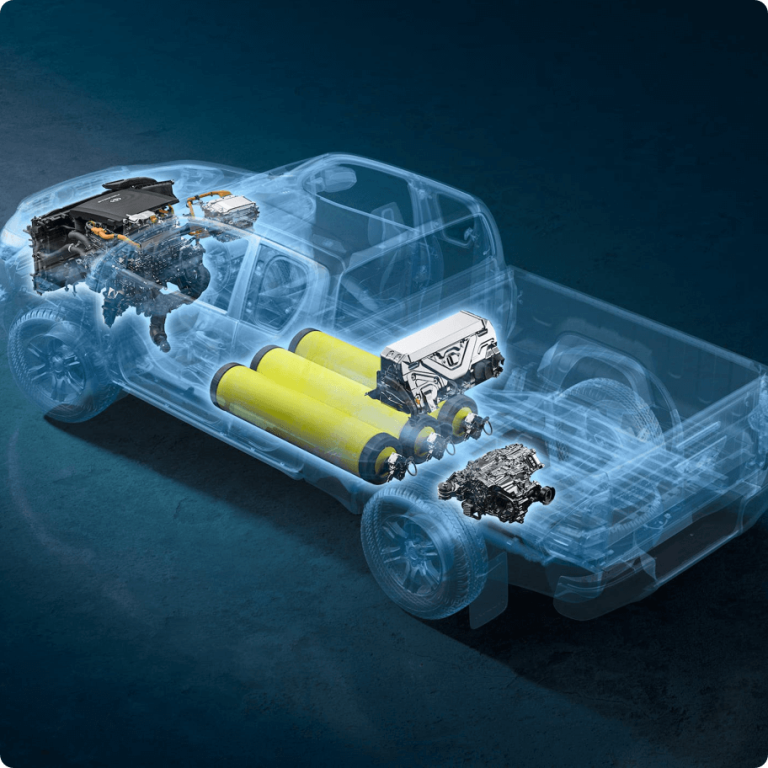

The graphite mold for hot-bent glass has a wide range of application fields in the glass manufacturing industry, such as the screen protective glass of electronic devices such as mobile phones, tablet computers, and televisions, automotive glass, and various types of architectural glass. Its superior performance characteristics significantly enhance the appearance, strength, and durability of glass products.

In the field of curved-screen mobile phones, the graphite mold for hot-bent glass plays an even more important role. Due to the appearance design requirements of curved-screen mobile phones, which need to meet higher flatness and curved-edge requirements, the high precision and curved forming ability of the graphite mold for hot-bent glass have become the key factors for achieving this design.

Summary

As an innovative technology in the glass manufacturing industry, the graphite mold for hot-bent glass brings revolutionary changes to the hot-bending forming of glass with its excellent high-temperature performance and precise geometric shape replication ability. With the continuous growth of market demand and technological progress, the graphite mold for hot-bent glass still has broad development prospects in the future and will bring more innovations and breakthroughs to the glass manufacturing industry.